The electronic measuring system revolutionizes modern repair standards, offering unparalleled precision and efficiency for car paint services and auto body repairs. It enhances accuracy in mapping defects, measuring thickness, and detecting inconsistencies, resulting in swift turnaround times and cost savings. This technology streamlines workflows, reduces errors, and enables detailed data analysis, making it a key differentiator in a competitive market. Future trends include AI integration for standardized, data-driven repair procedures, promising eco-friendly practices and consistent quality across service centers.

In today’s advanced automotive landscape, adopting modern repair standards is paramount. Among these, the electronic measuring system (EMS) stands out as a game-changer. This technology offers precise diagnostics and efficient repairs, enhancing workshop productivity while ensuring vehicle performance. This article delves into the basics of EMS, explores its significant advantages in repair processes, and examines future trends shaping industry standards. By understanding these developments, technicians can stay ahead, providing superior service with enhanced capabilities.

- Understanding Electronic Measuring System Basics

- Benefits of Integration in Repair Processes

- Future Trends and Industry Standards Evolution

Understanding Electronic Measuring System Basics

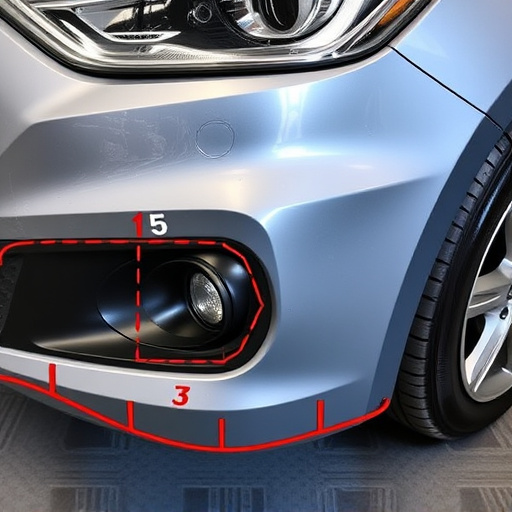

An electronic measuring system is a technological marvel that has transformed modern repair standards, particularly in the realm of car paint services and auto body repairs. This innovative tool acts as a crucible for precision, enabling professionals to achieve meticulous results with unmatched efficiency. By employing advanced sensors and software, these systems capture detailed measurements of vehicle surfaces, including complex shapes and contours, with remarkable accuracy.

This technology is especially valuable in the intricate process of car bodywork, where even minor inaccuracies can lead to subpar finishes. With its ability to swiftly and accurately map surface defects, measure paint thickness, and detect inconsistencies, the electronic measuring system revolutionizes how technicians approach repairs. As a result, clients benefit from enhanced quality, faster turnaround times, and more cost-effective car paint services.

Benefits of Integration in Repair Processes

The integration of an electronic measuring system into repair processes offers numerous advantages for both car repair shops and collision repair centers. By adopting advanced technology, these facilities can achieve greater precision and efficiency in their work. This is particularly beneficial when dealing with intricate repairs or precise adjustments, ensuring that every component is measured and installed accurately. The use of such systems streamlines the entire process, reducing the time required to complete a job while minimizing errors.

Moreover, an electronic measuring system allows for comprehensive data recording and analysis. This enables repair professionals to track their progress, identify trends, and make informed decisions based on accurate measurements. Such data can be invaluable in optimizing car repair services, improving overall quality control, and enhancing the reputation of the repair shop. In today’s competitive market, where customers demand top-notch service, this technological integration is a game-changer, setting apart those who embrace it from their competitors.

Future Trends and Industry Standards Evolution

As technology continues to march forward, the future of electronic measuring systems looks promising for the automotive industry and beyond. With advancements in sensor technology, we can expect more precise and efficient tools that aid in accurate measurements during repair processes. These innovations will not only enhance the quality of auto glass replacement and scratch repair but also revolutionize other aspects of vehicle maintenance. The integration of smart sensors and AI-powered systems could lead to standardized, data-driven repair procedures, ensuring consistency across different service centers.

Industry standards are poised for a significant evolution, shifting towards more digital and interconnected practices. This trend is already evident in the transition from traditional measuring tools to electronic alternatives, which offer greater efficiency and data capture capabilities. As such, future automotive repair services will likely rely heavily on these systems to meet growing demands for precision, speed, and environmental sustainability. These developments promise not only to streamline workflows but also to contribute to more eco-friendly practices in auto glass replacement and scratch repair processes.

The integration of an electronic measuring system into modern repair standards has brought about significant advancements in precision, efficiency, and accuracy. As we look to the future, ongoing evolution in technology will continue to shape industry standards, with continuous improvements in sensor capabilities, data analysis, and automation. This innovative approach ensures that repairs meet the highest quality thresholds, ultimately benefiting both businesses and consumers alike. An electronic measuring system remains a vital tool in keeping pace with modern repair demands.