The adoption of electronic measuring systems has dramatically improved structural measurements in industries like automotive repairs. These systems, employing advanced sensors and algorithms, surpass manual methods by offering unprecedented precision and efficiency. By eliminating human errors, streamlining processes, and enhancing structural accuracy, especially in body restoration and auto glass repair, these systems save time and money for both customers and repair facilities. In collision repair and auto painting, the shift to technologies like laser scanners and 3D imaging significantly raises work quality. For structural integrity tasks like tire and collision repairs, electronic measuring systems provide consistent accuracy, minimizing human involvement and enabling technicians to focus on intricate work, ultimately elevating automotive service standards.

In today’s digital era, the adoption of an electronic measuring system (EMS) is revolutionizing structural measurement, outpacing traditional manual methods. This article delves into the advantages EMS brings, focusing on precision, reliability, and efficiency. By employing advanced sensors, sophisticated data processing, and error reduction techniques, EMS sets a new standard for structural accuracy. Additionally, it streamlines processes, compressing project timelines and reducing costs through real-time feedback and quick adjustments, ultimately optimizing overall projects.

- Revolutionizing Structural Measurement: The Electronic Advantage

- – Discuss the traditional methods vs electronic measuring systems

- – Highlight the limitations and inefficiencies of manual measurements

Revolutionizing Structural Measurement: The Electronic Advantage

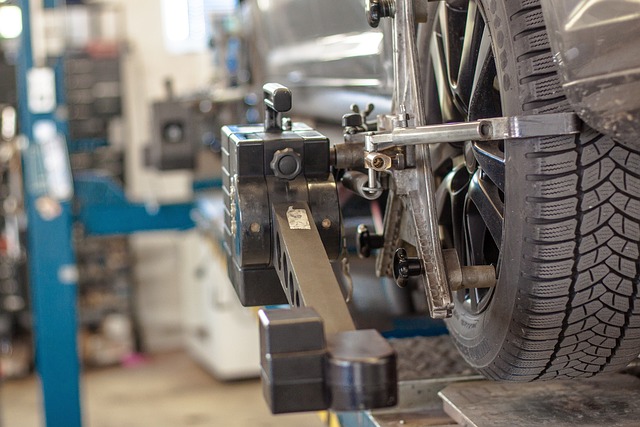

The advent of electronic measuring systems has revolutionized structural measurement in various industries, including automotive repairs. Traditional methods often relied on manual, time-consuming processes that were prone to human error. In contrast, electronic systems offer unparalleled precision and efficiency. They employ advanced sensors and software algorithms to capture and analyze data, ensuring accurate measurements every time.

This technology is particularly beneficial for tasks such as car body restoration and auto glass repair, where precise alignment and fitting are crucial. By replacing collision center practices that might involve rough estimates or imprecise tools, electronic measuring systems streamline the whole process. This not only enhances structural accuracy but also reduces the need for costly rework, thereby saving time and money for both customers and repair facilities.

– Discuss the traditional methods vs electronic measuring systems

In the realm of structural accuracy, especially within collision repair shops and auto painting facilities, the evolution from traditional measuring methods to electronic measuring systems has been transformative. Historically, professionals in auto repair shops relied on manual tools like tape measures, calipers, and rulers for precision work. While these tools served their purpose, they were time-consuming, prone to human error, and lacked the finesse required for intricate repairs.

Contrarily, electronic measuring systems bring a new dimension of accuracy and efficiency. These modern tools utilize advanced technology, such as laser scanners and 3D imaging, to capture detailed measurements quickly and precisely. This is particularly beneficial in auto painting applications, where achieving smooth, seamless finishes demands exacting dimensions. By eliminating the potential for human misinterpretation, electronic measuring systems ensure that every repair or modification is executed with meticulous care, ultimately enhancing the overall quality of work in collision repair shops and auto painting workshops.

– Highlight the limitations and inefficiencies of manual measurements

In the realm of structural integrity, manual measurements have long been the standard, but they come with inherent limitations and inefficiencies. Traditional methods often rely on human precision, which can be fallible due to factors like fatigue, distractions, or varying skill levels among technicians. This human element introduces potential errors, leading to less accurate results, especially in complex structural assessments. Moreover, manual measurements are time-consuming, requiring extensive labor and increasing the likelihood of delays in critical repair processes, such as those offered by tire services or collision repair services.

Car body restoration, for instance, demands meticulous attention to detail, and any miscalculation can compromise the overall quality. An electronic measuring system addresses these challenges head-on by offering unparalleled precision and efficiency. These systems utilize advanced technology, including sensors and software algorithms, to capture and analyze data with minimal human intervention, ensuring consistent and accurate measurements every time. By streamlining the measurement process, electronic measuring systems enable technicians to focus on more intricate aspects of their work, ultimately elevating the standards in tire services, collision repair services, and car body restoration.

Electronic measuring systems offer a significant leap forward in structural accuracy compared to traditional manual methods. By eliminating human error, increasing measurement speed, and providing precise data, these systems revolutionize the way we assess structures. The advantages are clear: improved efficiency, reduced costs, and enhanced overall project quality. Adopting electronic measuring technologies is not just a trend but a necessary step towards more accurate and reliable construction practices.